Что такое наклонно-направленная скважина в бурении нефтяных скважин?

Sep 17, 2025

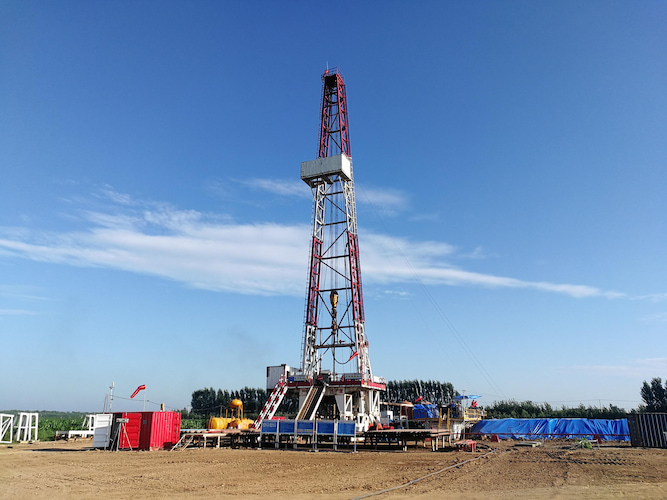

Технология направленного бурения (НБ) является одной из самых передовых технологий бурения в мировой сфере разведки и разработки нефти. Она основана на использовании специальных скважинных инструментов, измерительных приборов и технологических процессов для эффективного управления траекторией ствола скважины, направляя буровое долото к заданной подземной цели в заданном направлении. Эта технология устраняет ограничения вертикальных скважин, которые «могут разрабатывать только ресурсы непосредственно под устьем скважины». Внедрение технологии направленного бурения позволяет экономично и эффективно разрабатывать нефтяные и газовые ресурсы, ограниченные поверхностными или подземными условиями, значительно увеличивая добычу нефти и газа и снижая затраты на бурение. По сути, наклонно-направленная скважина — это метод бурения, который направляет ствол скважины к целевому пласту по заранее рассчитанному углу отклонения и азимуту.Существует три основных типа профилей скважин:(1) Двухсекционный тип: вертикальная секция + наращиваемая секция;(2) Трехсекционный тип: вертикальная секция + наращиваемая секция + касательная секция;(3) Пятисекционный тип: верхняя вертикальная секция + секция наращивания + касательная секция + секция спуска + нижняя вертикальная секцияГоризонтальная скважина — это тип наклонно-направленной скважины. Обычные нефтяные скважины вскрывают нефтяной пласт вертикально или под небольшим углом, что приводит к образованию короткого участка ствола, проходящего через пласт. В отличие от этого, после бурения вертикально или под углом для достижения нефтяного пласта, ствол горизонтальной скважины поворачивается в направлении, близком к горизонтальному, чтобы оставаться параллельным нефтяному пласту, что позволяет бурить большие расстояния внутри пласта до его завершения. Оснащена высокопрочными тяжелые бурильные трубы (HWDP) для горизонтальных участков и износостойкие долота PDC (поликристаллический алмазный компакт)Длина участка, вскрывающего пласт, может составлять от сотен метров до более 2000 метров. Это не только снижает гидравлическое сопротивление флюида, поступающего в скважину, но и многократно увеличивает производительность по сравнению с традиционными вертикальными или наклонно-направленными скважинами, способствуя повышению нефтеотдачи.Ⅰ. Сценарии применения1. Преодоление наземных/подземных препятствийПоверхностные препятствия: Если над резервуаром имеются здания, железные дороги, озера или экологические защитные зоны, то наклонно-направленные скважины можно бурить за пределами этих препятствий, чтобы достичь резервуара под углом (например, разработка нефтяных и газовых месторождений вокруг городов).Подземные препятствия: при обходе опасных геологических объектов, таких как подземные пещеры, соляные купола и разломы, ударопрочность и устойчивость к разрушению утяжеленные бурильные трубы и высокого давления противовыбросовый превенторs (ПБ) используются скоординированно, чтобы избежать аварий при бурении, таких как прихваты труб и выбросы.2. Увеличение производительности нетрадиционных месторождений нефти и газаНетрадиционные пласты, такие как сланцевый газ и нефть плотных пород, обладают «крайне низкой проницаемостью». Вертикальные скважины способны охватить лишь небольшую часть пласта, что ограничивает возможности добычи. Однако горизонтальные скважины пересекают пласт по горизонтали на расстояние в несколько сотен метров, увеличивая площадь контакта с пластом в десятки раз. Суточная добыча газа одной горизонтальной скважины может быть в 5–10 раз выше, чем у вертикальной, что делает её ключевой технологией для разработки нетрадиционных месторождений нефти и газа.3. Сокращение затрат на разработкуМорские месторождения нефти и газа: бурение куста скважин с одной морской платформы намного менее затратно, чем строительство отдельной платформы для каждого целевого объекта, что приводит к сокращению затрат на разработку на 30–50 %.Зрелые нефтяные месторождения: Благодаря технологии «sideTracking» (бурение ответвлений от ствола старой скважины для разработки оставшихся нефтяных пластов в близлежащей области) нет необходимости бурить новые вертикальные скважины, что значительно сокращает инвестиции.Ⅱ. Преимущества и недостатки по сравнению с вертикальными скважинамиПреимущества1. Широкие возможности охвата ресурсов: Он позволяет разрабатывать удалённые и разрозненные пласты, недоступные для вертикальных скважин, что позволяет повысить эффективность добычи нефти и газа из нефтяных и газовых пластов.2. Высокая производительность одиночной скважины: В частности, горизонтальные скважины значительно увеличивают площадь контакта между стволом скважины и пластом, обеспечивая значительные преимущества при разработке нетрадиционных месторождений нефти и газа.3. Превосходная экономическая эффективность: Кустовые скважины и многоствольные скважины, поддерживаемые интегрированными буровыми установками и соответствующим буровым оборудованием (таким как верхние приводы и буровой насосs), сокращают затраты на поверхностные работы и строительство платформы, что делает их пригодными для сценариев морской и интенсивной разработки.Недостатки1.Высокая техническая сложность: Для этого требуются профессиональные специалисты по направленному бурению, роторные управляемые системы (РУС) и оборудование MWD (измерения во время бурения), что приводит к гораздо более высоким техническим требованиям, чем для вертикальных скважин.2.Высокие затраты: Инвестиции в однонаправленную скважину обычно на 20–50 % выше, чем в вертикальную скважину той же глубины (из-за увеличения затрат на инструменты, оборудование и рабочую силу).3.Высокие риски: Сложная траектория приводит к высокому сопротивлению циркуляции бурового раствора и усложняет обеспечение устойчивости ствола скважины, что приводит к более высокому числу аварий, таких как прихват труб и обрушение ствола скважины, по сравнению с вертикальными скважинами.4.Длительный цикл строительства: Требуются частые корректировки траектории и измерения данных, что приводит к увеличению продолжительности цикла строительства на 30–60 % по сравнению с вертикальными скважинами той же глубины.Ⅲ. ЗаключениеПодводя итог, можно сказать, что наклонно-направленное бурение представляет собой важную веху в развитии нефтяной промышленности от простой вертикальной разработки до сложной и точной разработки. В настоящее время в мировой разработке нефтегазовых ресурсов доля применения наклонно-направленных скважин превысила долю вертикальных, что делает их одной из основных технологий обеспечения поставок нефти и газа.

ЧИТАТЬ ДАЛЕЕ

Language :

Language : Русский

Русский English

English عربي

عربي

Получить предложение

Получить предложение

IPv6 ПОДДЕРЖИВАЕТСЯ СЕТЬЮ

IPv6 ПОДДЕРЖИВАЕТСЯ СЕТЬЮ